Poultry Microbial Testing

Poultry processors need robust microbial detection solutions. Increasing demand requires effective and efficient solutions.

The stakes have never been higher for poultry processors charged with managing quality at the plant. As production volumes increase and efficient practices are required to stay competitive, active monitoring of microbial populations in raw poultry has become commonplace. And ensuring ready-to-eat products are pathogen free is an everyday challenge.

Complex matrices in the poultry industry pose unique challenges

FSMA has placed a greater emphasis on preventive quality controls that include early detection coupled with rigorous microbial reduction programs. However, most poultry microbial rapid detection methods available today are inefficient or struggle to accurately identify microbes in difficult matrices such as boot or fecal swabs, carcass rinsates and processed products like broths and MDM.

Proven platform delivers accuracy, speed, and sensitivity

The Veriflow suite of food protection tools is powered by game-changing technology designed specifically for the food safety industry, utilizing proven diagnostic principles for microbial detection in an accessible format for streamlined onsite testing. In particular, Invisible Sentinel has placed specific emphasis on partnering with poultry processors. The robust platform performs at the highest levels of accuracy in even the most challenging poultry matrices, with simplified sample preparation and user-friendly workflow. Veriflow technology is AOAC International Certified for foodborne pathogen detection and has been widely adopted by food manufacturers and global 3rd party testing labs.

Portfolio of products targeting microbes of concern for poultry processors

Extensive testing was conducted on all Veriflow assays to demonstrate the sensitivity of each product. The Veriflow portfolio of microbial detection tests perform at the highest levels of accuracy with zero reported false positive or false negative results observed in validation studies. AOAC Performance Tested MethodsSM Program was utilized for verification of assay performance.

* Including stainless steel, sealed concrete, plastic and ceramic tile.

Proven performance in our customers’ hands

Veriflow has been implemented in numerous poultry processing facilities in the US. The technology enables early action at critical control points to increase manufacturers’ confidence in product quality and brand integrity.

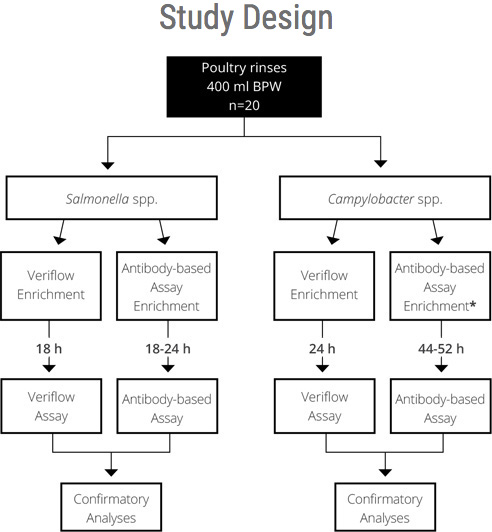

Comparative study on the accuracy and specificity of Veriflow technology for pathogen detection in poultry processing

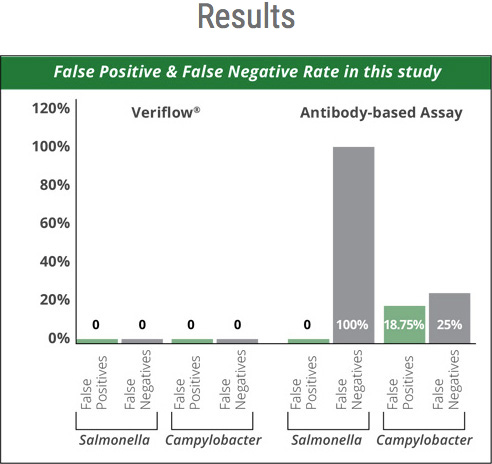

A comparative study was conducted at a poultry processing facility to assess the performance of two rapid methods, Veriflow platform and an antibody-based platform, for the detection of Salmonella species and Campylobacter in raw poultry parts. Discrepant results were further analyzed by USDA-FSIS MLG Reference methods. Veriflow did not produce any false positive or false negative results for either pathogen. Whereas, the antibody-based method did not detect any of the 7 positive results in the Salmonella study, and resulted in an 18.75% false positive and 24% false negative rate respectively, in the Campylobacter study.

In conclusion, the Veriflow platform proved to be a more accurate and user-friendly rapid diagnostic method for the detection of Salmonella and Campylobacter in raw poultry samples.

Access the full Poultry Comparative White Paper here.